How to calculate your business's cold storage needs

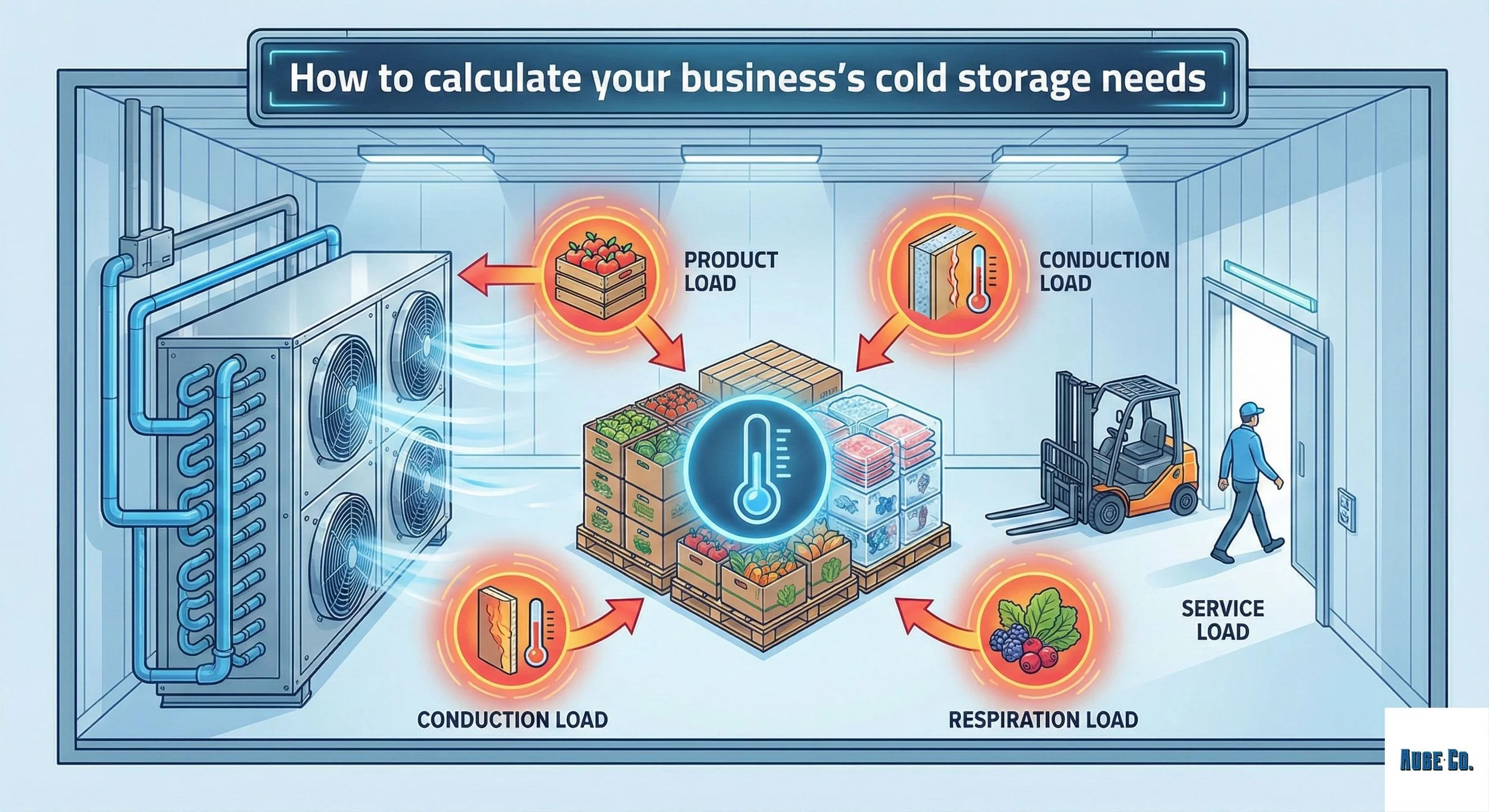

To accurately calculate your cold storage needs, you must shift your focus from measuring physical space to calculating the total thermal energy your facility must overcome. This involves a comprehensive thermal load calculation that accounts for four key heat sources: the heat from incoming products, heat leaking through the structure, heat generated by daily operations, and heat produced by respiring goods like fresh produce. This approach ensures your refrigeration systems are powerful enough for your busiest days, preventing costly product loss and energy waste.

The 'Cubic Foot Fallacy': Why Your Pallet Count is a Deceptive Metric

For years, the standard approach to planning a cold storage facility has started with a simple question: "How many pallets do you need to store?" From there, planners would perform a pallet position calculation for cold storage, determine the necessary square footage, calculate the cubic volume, and select a refrigeration unit that lists a similar capacity. This is the 'Cubic Foot Fallacy'—the dangerous assumption that volume is the most important variable in refrigeration.

This method treats a dynamic, thermally complex environment like a static, empty box. It completely ignores the energy required to cool the products themselves, the heat generated by your own team and equipment, and the constant thermal assault from the outside world. This oversight is a primary reason why so many businesses face system failures during peak demand. Your facility might have the physical space for 500 pallets, but if your refrigeration equipment was sized only for the space, it will be critically underpowered when those 500 pallets of produce arrive straight from a hot field on a summer afternoon.

The consequences of this miscalculation ripple through the entire supply chain. An undersized system runs constantly, driving up energy costs while failing to maintain a stable temperature. This leads to premature product spoilage, loss of inventory, and potentially jeopardizes compliance with regulations like the Food Safety Modernization Act (FSMA). Conversely, guessing too high isn't a safe bet either. As efficiency experts will confirm, an oversized refrigeration system wastes money on unused capacity through higher upfront equipment costs and inefficient energy cycling. A proper cold storage needs assessment template must go beyond simple dimensions.

A Better Metric: Deconstructing Your Total Heat Load

The solution is to stop measuring space and start measuring heat. The professional standard for sizing commercial refrigeration systems is calculating the total 'heat load' or 'thermal load' of the facility. This figure represents the total amount of heat energy that must be removed from the space every hour to maintain the desired temperature. A heat load is typically given in units of BTU/hr (British thermal units per hour) or Watts. Completing a cold storage BTU calculation gives your contractor the precise data needed to engineer a system that is both powerful and efficient.

A comprehensive refrigeration load calculation for a cold room is not a single number but the sum of several distinct parts. The refrigeration load includes four basic factors, which must be determined individually and then totaled: field heat, respiration heat, conduction heat, and service heat. Let's break down each component.

1. Product Load (The Heat Your Goods Bring In)

Product load, often called 'field heat', is the thermal energy contained within the goods you bring into the cold storage facility. Every item—from a crate of pharmaceuticals to a pallet of frozen food—arriving at a temperature higher than your storage temperature introduces heat that your system must remove. The calculation involves the product's mass, its specific heat (the energy needed to change its temperature), and the temperature difference between its arrival state and the target storage temperature. For distributors and those in food and beverage manufacturing, this is often the single largest component of their heat load.

2. Conduction Load (The Unseen Heat Leaking In)

Heat naturally moves from warmer areas to cooler areas. Conduction load is the heat that infiltrates your cold room through the walls, floor, and ceiling. This heat transfer is a constant battle. Its magnitude depends on three things: the total surface area of your facility, the quality of your insulation (its R-value), and the temperature differential (the difference between the outside ambient temperature and your internal set point). This is a critical factor in any lease vs build cold storage cost analysis, as a well-constructed building with high-performance insulation panels will have a significantly lower conduction load and, therefore, lower long-term operational costs.

3. Service Load (The Heat of Doing Business)

Every action taken inside your temperature-controlled warehouse generates heat. This is the service load, and it's a composite of several operational factors. It includes the body heat from employees working in the space, the energy emitted from lights (which is why switching to energy-efficient LED lighting is crucial for industrial refrigeration energy efficiency), and heat from equipment like forklifts, fans, and conveyor belts. A major, and often underestimated, part of the service load comes from door openings. Every time a door opens, warmer, more humid air rushes in, forcing your refrigeration systems to work harder. Accurately assessing product velocity for cold storage and the frequency of door cycles is essential for a precise calculation.

4. Respiration Load (The Heat of Living Products)

This factor is critically important for anyone storing fresh fruits and vegetables. Many people forget that harvested produce is still a living organism. As agricultural experts note, storage crops are living organisms and they respire. Respiration gives off heat and moisture. Different products have wildly different respiration rates. For example, berries, leafy greens, and broccoli generate a tremendous amount of heat, while apples and potatoes respire at a much lower rate. This is a non-negotiable part of any temperature sensitive product storage planning for growers, packers, and grocery distributors.

Comparing the Methodologies: Space vs. Heat

Understanding how to choose a cold storage contractor often comes down to the methodology they propose. Here is a direct comparison of the two approaches to determining your facility needs.

Method 1: The Space-Based Approach (Cubic Feet)

Pros: This method is simple to understand and communicate. It's useful for initial conversations about optimizing cold storage warehouse layout and for very basic cold storage capacity calculator tools. It helps in how to calculate pallet storage capacity in a purely physical sense.

Cons: As a basis for refrigeration engineering, it is dangerously incomplete. It ignores all thermal dynamics, which is like designing a boat based on its cargo capacity without considering the weight of the cargo or the currents of the ocean. This approach frequently leads to undersized systems that fail during peak demand, resulting in high energy bills and catastrophic product loss.

Method 2: The Heat Load Approach (BTU/hr)

Pros: This is the engineering gold standard. It provides a scientifically accurate measure of the work your refrigeration equipment must perform. It ensures your system is resilient and can handle your busiest day, protects your inventory, and leads to superior energy efficiency by right-sizing commercial refrigeration systems. This method is foundational for predictive modeling for cold storage demand and long-term expansion planning for cold storage facilities.

Cons: A proper cold room size calculation formula based on heat load is more complex and requires significantly more data about your specific products and operational workflows. It often requires the expertise of an experienced refrigeration engineer or a qualified cold storage contractor to perform accurately.

Calculating for Your Busiest Day, Not Your Average One

One of the most critical mistakes in cold storage planning is designing a system for an average day. Your facility doesn’t operate on averages; it operates in a world of peaks and valleys. Sizing your system for a quiet Tuesday in October is a guaranteed recipe for failure on a frantic Friday in July when ambient temperatures are at their highest and you receive three unexpected truckloads of product. This is why a core part of any supply chain cold storage assessment is modeling a "peak day scenario."

To do this, you must project your maximum operational intensity. What is the highest anticipated outdoor temperature your facility will face? What is the largest volume of warm product you could possibly receive in a single 24-hour period? How many people and forklifts will be working during your peak shift? How many times per hour will your main doors be open? Building a resilient cold chain means planning for these moments of maximum stress. This is where true reliability is forged. We've seen it firsthand; a client once called us in a panic, saying, "These guys are the BEST! Helped me out when our driver's clutch went out! Unloaded and loaded our new driver in no time! Reach out to them if you're ever in a pinch." That emergency situation was their unplanned peak day, and having a robust third-party logistics (3PL) cold storage partner with adequate capacity made all the difference.

Answering Your Core Financial Questions

Ultimately, this planning exercise is about making a sound financial decision. Let's address some of the key questions business owners have when considering a new facility or a system upgrade.

How much money is required for a cold storage facility?

The cost to build or expand a cold storage facility varies dramatically based on size, location, and technological sophistication. Key costs include the cold storage construction cost per square foot, which is higher than for standard warehouses due to specialized insulation and structural requirements. Then there's the cost of the industrial refrigeration equipment itself, as well as essential components like insulated doors, dock seals, and potential cold storage automation systems. It is vital to properly budget for a new cold storage facility by getting detailed quotes based on a thorough heat load analysis, not just a square footage estimate.

What is the ROI of a right-sized cold storage investment?

Calculating the ROI on cold storage investment goes beyond simple profit margins. The most significant returns come from avoided losses. A right-sized system prevents product spoilage, which can be a massive financial drain. Furthermore, an energy-efficient refrigeration solution will significantly lower your monthly operational cost breakdown. A reliable cold storage solution also enhances your reputation, allowing you to secure more business and grow your operations. Improved efficiency, reduced waste, and increased capacity all contribute to a powerful and compelling return on investment.

Making the Right Choice for Your Needs

There is no single formula or universal solution that fits every business. The right approach depends entirely on your products, your operations, and your goals. A cold storage contractor evaluation checklist should always begin with understanding if a potential partner appreciates these nuances.

For the Commercial Grower/Packer

Your primary concern is the massive and immediate influx of heat. You are dealing with a huge 'Product Load' from field heat and a significant, ongoing 'Respiration Load' from large quantities of living produce. For you, a detailed heat load calculation is absolutely non-negotiable. Your entire business depends on rapidly and efficiently removing this heat to preserve the quality and shelf life of your harvest.

For the 3PL/Warehouse Manager

Your focus is on overall facility efficiency and managing a highly variable operational tempo. You contend with a substantial 'Service Load' from constant forklift traffic, frequent door openings, and 24/7 lighting. You must also manage the 'Conduction Load' of a large building. For you, a heat load analysis is key to optimizing energy consumption and avoiding the high costs associated with an oversized system that wastes energy during slower periods.

For the Small-Scale Producer

You may be dealing with a smaller, well-insulated walk-in cooler or a converted room. While a full engineering study might seem excessive, understanding the basic principles of heat load is still critical. You need to account for the specific respiration heat of your crops—some, like squash, can even self-heat a space. A basic cold storage solution for a small business still benefits from considering all four heat sources to ensure product safety and avoid unexpectedly high electricity bills.

Ultimately, the best choice depends on your unique situation. For over two decades, Auge Co. Inc. has been the trusted logistics partner for businesses designing and managing their cold chain. Our expertise in performing a comprehensive needs analysis for a cold storage warehouse ensures your facility is built for performance, not just for size. If you're looking for a national logistics partner you can count on or are located near San Antonio, TX, contact our expert team today for a personalized assessment and a free quote.