What are the five types of cross-docking?

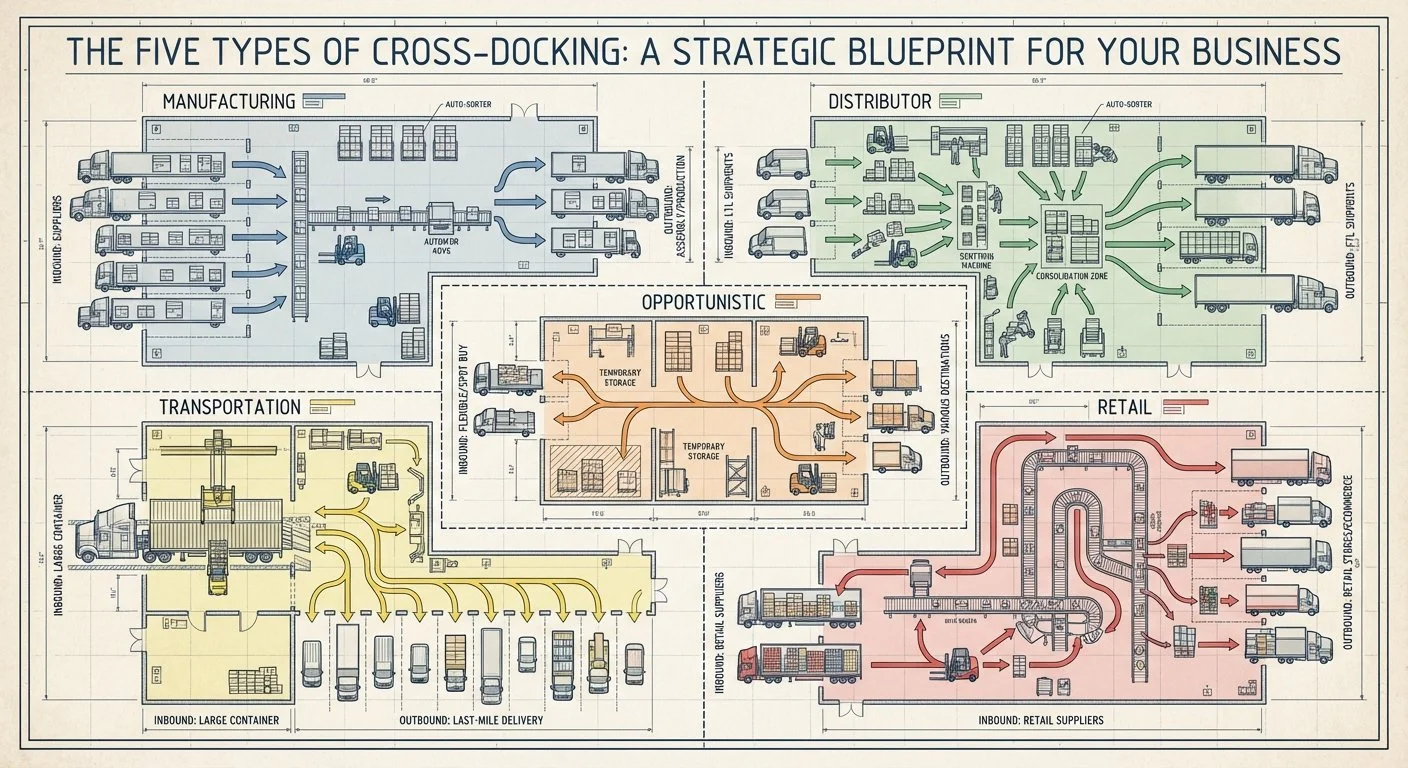

The five primary types of cross-docking are Manufacturing, Distributor (Consolidation), Transportation (Deconsolidation), Retail (Continuous), and Opportunistic. Each type serves as a unique strategic blueprint designed to solve specific business challenges, aligning your supply chain directly with market demands rather than just warehouse efficiency.

Moving Beyond the Warehouse: Cross-Docking as a Business Strategy

For three decades, we at Auge Co. Inc. have seen countless businesses view their distribution center as a simple cost center—a place for storage and handling. But the most successful operations understand that a warehouse, specifically its loading dock, is a strategic asset. Cross-docking is the ultimate expression of this mindset. The underlying idea of cross-docking is to efficiently sort and dispatch packages to provide faster delivery of goods from supplier to end customer. It's about velocity, reducing inventory carrying costs, and creating a lean, responsive supply chain.

However, the conversation often stops at defining the "what." Many articles list the types of cross-docking as if they are items on a menu. The real information gain comes from understanding the "why"—seeing each type not as a warehouse process, but as a direct solution to a specific business model's needs. The 'best' cross dock strategy is the one that mirrors your company's promises to its customers.

The 5 Types of Cross-Docking: A Blueprint for Different Business Models

Let's map the five core types of cross-docking to the business challenges they are engineered to solve. This is the business model matrix in action, where operational tactics align with strategic goals.

1. Manufacturing (Pre-Distributed) Cross-Docking

In this model, inbound products are received already sorted and labeled for their final destination. The cross-docking terminal functions as a simple transfer point. Unloading from inbound trucks, minimal handling in a staging area, and immediate loading onto outbound trucks is the entire process. This requires immense coordination and a highly reliable supplier network, often leveraging tools like an Advance Ship Notice (ASN) and barcode scanning for seamless receiving. This is the heart of a Just-In-Time (JIT) inventory system.

Business Model Fit: Assembly and Manufacturing Operations (e.g., Automotive). Imagine an auto plant. It doesn't need a stockpile of 10,000 steering wheels. It needs the right 500 steering wheels for the cars being assembled today. Pre-Distributed Cross Docking works great for businesses with predictable demand and a reliable supplier network, making it the backbone of lean manufacturing.

2. Distributor (Consolidation) Cross-Docking

This is a classic hub and spoke model in practice. The cross-docking facility receives multiple smaller shipments, often Less-Than-Truckload (LTL), from various suppliers. These goods are then combined and sorted into larger, more economical shipments, like a Full Truckload (FTL), for delivery to a specific destination, such as a single retail store or fulfillment center. This is a powerful strategy for cost reduction in freight consolidation.

Business Model Fit: B2B Suppliers and E-commerce Aggregators. A business that supplies components to retailers receives products from ten different small manufacturers. Instead of sending ten separate LTL shipments to a big-box store and incurring high transportation costs, they use a consolidation point to create one efficient FTL shipment. This directly improves margins and operational efficiency.

3. Transportation (Deconsolidation) Cross-Docking

As the name implies, this is the reverse of consolidation. A large inbound shipment, such as an FTL or a container of imported goods, arrives at the cross-docking terminal. The products are then broken down, sorted, and loaded onto multiple smaller delivery trucks for last mile delivery to various individual customers or businesses. This process is critical for e-commerce fulfillment and requires sophisticated sortation technology within the warehouse management system (WMS).

Business Model Fit: E-commerce and Direct-to-Consumer (DTC) Brands. A company imports a container of popular electronics. Instead of storing them, the container is moved to a cross dock facility where the goods are immediately sorted into individual customer orders and dispatched via local delivery vehicles. This greatly accelerates the order fulfillment cycle time.

4. Retail (Continuous) Cross-Docking

This is cross-docking at its fastest pace. It involves a constant, high-volume stream of products moving through the distribution center with little to no time spent in a staging area. Think of a conveyor system moving goods directly from an inbound dock door to an outbound dock door. This model is essential for businesses dealing with fast-moving consumer goods (FMCG), especially perishable goods with a short shelf life. Success here depends on stable, high demand and exceptional coordination enabled by a Transportation Management System (TMS).

Business Model Fit: Large Grocery Chains and Big-Box Retailers. For a major supermarket, this method is mission-critical. Continuous (Non-Stop) Cross Docking is described as 'perfect for businesses with high-volume products that need to keep moving, such as grocery stores or large retailers.' It ensures fresh produce arrives daily without languishing in storage, minimizing spoilage and maximizing throughput.

5. Opportunistic Cross-Docking

This is the most flexible and adaptive form of cross docking. It isn't a planned, daily process but rather a solution applied as needed to a specific inbound shipment to fulfill a known, urgent demand. For example, a customer places a rush order for a product that just arrived on an inbound truck. Instead of the standard putaway and picking process, those goods are diverted directly from the receiving dock to the outbound shipping dock to meet the immediate need.

Business Model Fit: Fast Fashion, Promotional Sales, and Emergency Logistics. This model is perfect for businesses that need to react to sudden market changes. It's also an invaluable tool for any third-party logistics (3PL) partner focused on problem-solving. We once had a client whose truck broke down unexpectedly. As they told us, "These guys are the BEST! Helped me out when our driver's clutch went out! Unloaded and loaded our new driver in no time! ... 10/10!!!" That rapid response is the essence of opportunistic cross-docking—turning a potential disaster into a seamless transition.

Choosing Your Blueprint: Key Strategic Factors

Deciding which model fits your business isn't a simple choice between warehouse-centric efficiency and a market-driven strategy; it's about aligning them. A purely efficiency-focused approach might create a fast warehouse that ships the wrong products to the wrong market. A market-driven strategy without operational excellence leads to broken promises. Here are the key factors to weigh:

Demand Predictability and Stability

How consistent is the demand for your products? As research confirms, cross-docking is most effective for products with stable demand rates and low stock-out costs. If your demand is steady, like a grocery store's need for milk, a continuous model is ideal. If it's volatile, like for seasonal fashion, an opportunistic or consolidation approach offers more flexibility.

Shipment Volume and Size

Do you primarily deal with large FTL shipments from a few suppliers or many small LTL shipments from a wide network? Your answer points directly toward either a deconsolidation or consolidation strategy. The goal is to minimize handling costs and maximize transportation savings for the types of shipments you manage most.

Supplier Network Reliability

How much control and visibility do you have over your inbound logistics? A pre-distributed model relies on suppliers sending perfectly packed and labeled shipments on a precise schedule. If your supplier network is less mature or reliable, a model like distributor cross-docking provides a buffer to sort and organize goods before final outbound shipping.

Need for Market Flexibility

How quickly does your market change? A fast-fashion retailer must be able to pivot inventory on a dime to meet new trends. An automotive manufacturer values stability and predictability above all. Your need for agility will dictate whether a rigid, continuous process or a flexible, opportunistic one is the right fit.

The Reality of Modern Logistics: The Hybrid Approach and Broader Concepts

Sophisticated supply chains rarely use one "pure" type of cross-docking. The most effective logistics network often blends these models. A large retailer might use continuous cross-docking for its top-selling pantry staples, a consolidation model for general merchandise from smaller vendors, and an opportunistic approach for holiday promotions. This hybrid strategy allows them to achieve both efficiency for their core business and flexibility for new opportunities, truly optimizing their supply chain management (SCM).

This strategic thinking also connects to broader logistics concepts. While there isn't a universally agreed-upon list of "5 supply chains" or "5 P's of logistics," the principles overlap. The choice of a cross-docking model is influenced by the 5 P's (Product, Price, Promotion, Place, and People/Process) and must be supported by the five primary modes of transportation (road, rail, air, water, and pipeline) to function. The ultimate goal is to create a supply chain that is lean, agile, and aligned with your overall business objectives.

A Quick Diagnostic: Is Your Strategy Misaligned?

Ask yourself these three questions to determine if your current logistics strategy is supporting or hindering your growth:

Does our inventory flow match our customer's buying rhythm? If you sell predictable, high-volume goods but hold them in storage for weeks, your costs are too high. You are misaligned with a continuous or pre-distributed opportunity.

Are our transportation costs growing faster than our sales? If you're sending dozens of small LTL shipments to the same region, you are missing a massive cost-saving opportunity that a consolidation model provides.

Can we capitalize on a sudden market opportunity within 48 hours? If a competitor has a stock-out or a new trend emerges, can your supply chain react? If not, you lack the flexibility that an opportunistic approach builds into your operation.

Making the Right Choice for Your Needs

There is no single "best" type of cross-docking. The right choice is a strategic one, dictated by the demands of your specific business model. The fundamental goal, as some academics put it, is to master the process of consolidating products coming from different suppliers, but having the same destination, with minimal handling and almost no storage. How you achieve that depends entirely on your context.

The High-Volume Grocer: This business lives and dies by freshness and availability. They require a continuous, non-stop flow of perishable goods with predictable demand to keep shelves stocked, making Continuous Cross-Docking a strategic necessity.

The E-commerce Aggregator: This business model is built on variety and cost-efficiency. They receive many small shipments from various suppliers and must combine these into larger, cost-effective outbound shipments, making Consolidation Cross-Docking the ideal model to protect margins.

The Fast-Fashion Retailer: This company must adapt to rapidly changing customer trends and real-time demand. The ability to quickly pivot and move specific, high-demand products from receiving to shipping is essential, making the flexibility of Opportunistic Cross-Docking central to their success.

Ultimately, choosing and implementing the right cross-docking strategy is about finding a logistics partner who understands your business, not just your boxes. With 30 years of experience helping companies build more responsive and efficient supply chains, we at Auge Co. Inc. know how to align warehouse operations with market-winning strategy. If you're ready for a personalized assessment of your logistics needs, contact our expert team in San Antonio, TX, for a conversation and a reliable quote.